From one-man operation to market leader

1967

In 1967 the single-member company HU. Grünig is founded, with the purpose to carry out general building locksmith work and to manufacture garage doors. The garage of his in-laws serves as a workshop. In May 1967 the first staff member is employed.

1968

Hans-Ulrich Grünig’s ideas for technical and mechanic innovations bring him in contact with the company Harlacher. During a first phase, they let him manufacture mechanical elements and at a later date develop and build entire machines.

1971

A bigger workshop is needed. At Schönenbuchen, not far from Schwarzenburg, the corresponding premises can be found.

1974

Elisabeth Grünig joins the company, taking over the responsibility for human resources and accounting.

Restructuring of the one-man operation into the stock company „HU. Grünig AG“ with a share capital of CHF 100‘000.--, owned by Hans-Ulrich and Elisabeth Grünig.

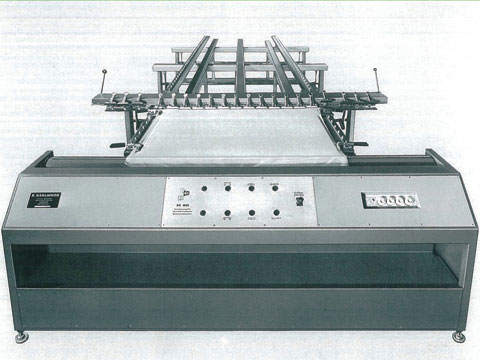

1974

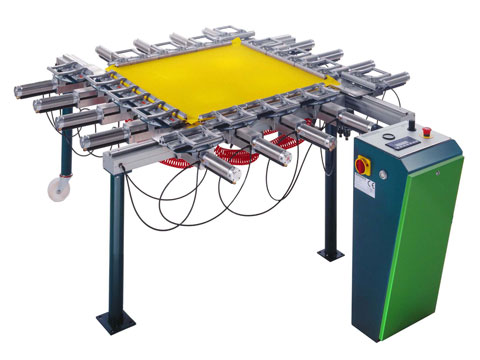

Presentation of the first large-surface stretching machine H-28

1977

The municipality of Wahlern sells 2000 m2 of building land to „HU. Grünig AG“ 2000 m2 located at Ringgenmatt

Hans-Ulrich Grünig and his children Marcel and Astrid during the ground-breaking ceremony

1978

Construction of the factory hall with a usable floor space of 1600 m2

1979

Development and construction of the worldwide first coating machine H-41

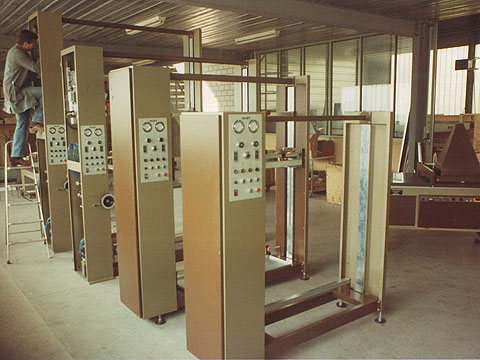

1979

Inauguration of the factory workshop; the workforce consists of 16 members

1984

Development and production of the explosion-proof screen washing machine H-11

1986

Sale of the first screen de-coating machine H-12

1988

Thanks to the extension of the factory workshop by 700m2, the operations can be restructured and the individual departments get more working space.

1988

The first CNC processing center is purchased. Now we are also in a position to manufacture sophisticated parts in an economic manner.

1988

The fully automatic coating machine H42 is presented at the FESPA trade fair in Amsterdam. It is the first system that features automatic screen feeding and offers the possibility of mixed operation, i.e. to handle three different screen formats.

However, it is still early times and 10 additional years will be needed till the pre-print stage can be automated on a larger scale.

1989

The time of the drawing boards is finally a thing of the past: AutoCAD 9 is purchased.

1991

Development of the washing machines G-11E, G-12E und G-15E with vertically moving roller shutter

Production and sale of washing systems on our own account and under the brand name of "Grünig"

1992

25th anniversary of the company; the workforce consists now of 32 members

Foundation of the distribution company "Interscreen AG"

Launch of the brand «Grünig» and first trade fair appearance during the FESPA in Amsterdam

1993

Termination of the cooperation with the company Harlacher

The washing systems are revised and the first equipments of types G11L and G12L are sold.

1993

New development of the coating machine G-420

1994

Acquisition of the adjacent real estate property, construction of the showroom

1994

New development of the mechanical stretching device G-210

1994

The range of coating machines is completed by the types G-405 and G-411.

The first developing machine of type G-15L is sold.

1995

Merger of the companies "HU. Grünig AG" and "Interscreen AG" into "Grünig-Interscreen AG", which with a share capital of CHF 200'000 remains in the ownership of the Grünig family

Introduction of the new company logo

1995

The stretching machine G-280A is developed. Thanks to the integrated measuring system, it is possible for the first time to stretch a mesh up to a predefined end value in a fully automatic manner.

1995

The CD industry is booming, and large quantities of printing screens are required. With their G-600, Grünig offers an efficient in-line solution for de-greasing and coating the screens.

1996

The G-215, a pneumatic stretching system based on the well-proven stretching device G-210 is launched; as an option, it can be equipped with an automatic stretching mechanism.

1999

Marcel Grünig supersedes his parents as owner of the company.

1999

Automation in the CD sector continues unabated. The recently developed stretching and gluing system G-260 sets new standards.

2000

The demand for ever bigger equipment is steadily increasing. The new coating machine G-421 takes into account this market situation, replacing the G-420 after seven years.

3600m2 of building land are purchased for the second building extension

2000

With the G-125, it is now possible to develop and de-coat screens with a size of up to 5x12m

2001

The development of the modular In-Line washing system G-170 opens up new perspectives for automatic screen cleaning.

2002

Handover of the operative management to Marcel Grünig (CEO and chairman of the board) and to Andreas Ferndriger (member of the managing committee)

Hans-Ulrich Grünig retires from the active business.

2003

The product range is amplified in the smaller size segment, too. The coating machine G-404, which is in a position to coat screens with a maximum height of 1.5m, is so easy to install that it is marketed under the slogan "Plug & Coat".

2004

The story goes on with "Plug & Wash". As it has been designed for maximum ease of installation, the newly developed G-104 can easily be mounted by the customer himself. The machine is available in two versions, i.e. for washing or developing, and in four different sizes for screen widths ranging from 0.75m, to 1m, 1.25m up to 1.5m. The uniform workable screen height is 1.4 m.

Change-over to 3D-CAD

2005

The newly elaborated Corporate Design confers a fresh and distinctive identity to the company and their equipment.

The new corporate image is presented for the first time during the FESPA exhibition in Munich.

2005

The modular in-line washing system G-WASH 140 is launched on the market. Due to its high degree of modularity, the system can be easily adapted to meet almost any requirement.

This is also the year when the inclined filter G-WASH 040 is developed; it allows a continuous cleaning of the washing liquids.

2006

With a view to accommodate the growing size of the equipment and to optimize the manufacturing sequences and procedures, the construction work for the second building extension is started.

Elisabeth Grünig retires from the active business.

2006

The stretching machine G-280 is revised. Thanks to the lower construction height and the state-of-the-art technology on which the new G-STRETCH 281 is based, the ergonomics and ease of handling of the machine can be considerably enhanced. The welded transversal stretching beams are replaced by an aluminum support that has been specially developed for this purpose.

2006

Plug & Strip is the motto of the new de-coating, developing and de-greasing machine G-WASH 112.

2007

On the occasion of the 40th company anniversary, international partners, suppliers as well as the local population is invited for "Open House Day"; at the same time, the new production hall with a surface of 1400m2 is inaugurated.

In the mean time, the workforce counts 40 staff members.

2007

Eight years after the launch of the G-260, the G-STRETCH 270 is developed; for the first time, an automated gluing of meshes and the processing of large-size screen frames by means of UV glue is now possible. It is the first machine in the company’s history which is controlled via a Windows interfaced.

2008

Sale of the 4000th Grünig machine

2009

Presentation of the G-PREP 370: With a water pressure of 1500 bar, screen cleaning is now possible in a hardly imaginable quality and with maximum efficiency.

2010

When used in combination with the screen handling system G-LINE 190XS, the newly developed in-line washing system G-WASH 170XS offers a hitherto unrivalled flexibility with regard to scalability and integration of CTS systems. Screen sizes of up to 2x3m can be handled.

The ERP system is introduced.

2010

With the market launch of the G-COAT 415, the production of the G-405 and G-411 models is discontinued. The new machine concept can be completed by various options; in the corresponding execution it is even in-line-compatible.

2011

Marcel Grünig and Andreas Ferndriger invest in Sign-Tronic AG, initializing the strategic cooperation between both companies.

2013

Thanks to the development of the G-WASH 150, it is from now on possible to wash rotation screens for label printing. The machine features two washing chambers through which the screens are automatically conveyed by a transport system.

The in-line washing system G-WASH 130 for the US textile market is developed.

2013

100 % of the share package of the company Sign-Tronic AG is taken over by Marcel Grünig and Andreas Ferndriger. Andreas Ferndriger is appointed new managing director of Sign-Tronic AG.

2015

The gluing technique continues to evolve. The G-STRETCH 275 and the UV-LED gluing head which were developed from scratch enable the printers to process not only open meshes but also previously coated meshes.

2016

With the G-WASH 170XM, the company launches an in-line washing system for screen formats between 2x3m and 3x6m; it replaces the existing G-170. Other than its high level of modularity, this model distinguishes itself by the fact that the big washing chambers can be disassembled, so that from now on standard containers can be used for transporting the equipment.

2016

The G-WASH 130 is revised and its level of modularity considerably increased.

The DMS system is introduced.

2017

The 50th company anniversary is celebrated together with customers and partners during the FESPA trade fair in Hamburg.

All the staff members are rewarded for their efforts with a company trip to Portugal.

2018

Expansion of the attractive PLUG & COAT product range with the G-COAT 406

2018

Expansion of the attractive PLUG & WASH product range with the G-WASH 106

2020

Increased professionalism is also required in the final step of the stencil manufacturing process. World novelty G-PROOF 390.

2021

G-COAT 414 closes the gap between G-COAT 406 and 415 and covers double-sided coating up to medium formats.

DE

DE  EN

EN