For 50 years already, Grünig has been dedicated to the professional screen preparation on a worldwide level. During all these years, the screen printing process has been exposed to various tendencies, changes and challenges. In the meantime, a lot has changed in this field as well as in the company: From the initial and purely mechanical one-man operation, it has evolved into a high-tech specialist.

For 50 years already, Grünig has been dedicated to the professional screen preparation on a worldwide level. During all these years, the screen printing process has been exposed to various tendencies, changes and challenges. In the meantime, a lot has changed in this field as well as in the company: From the initial and purely mechanical one-man operation, it has evolved into a high-tech specialist.

The beginnigs

1967 Hans-Ulrich Grünig starts his own company in a small garage.

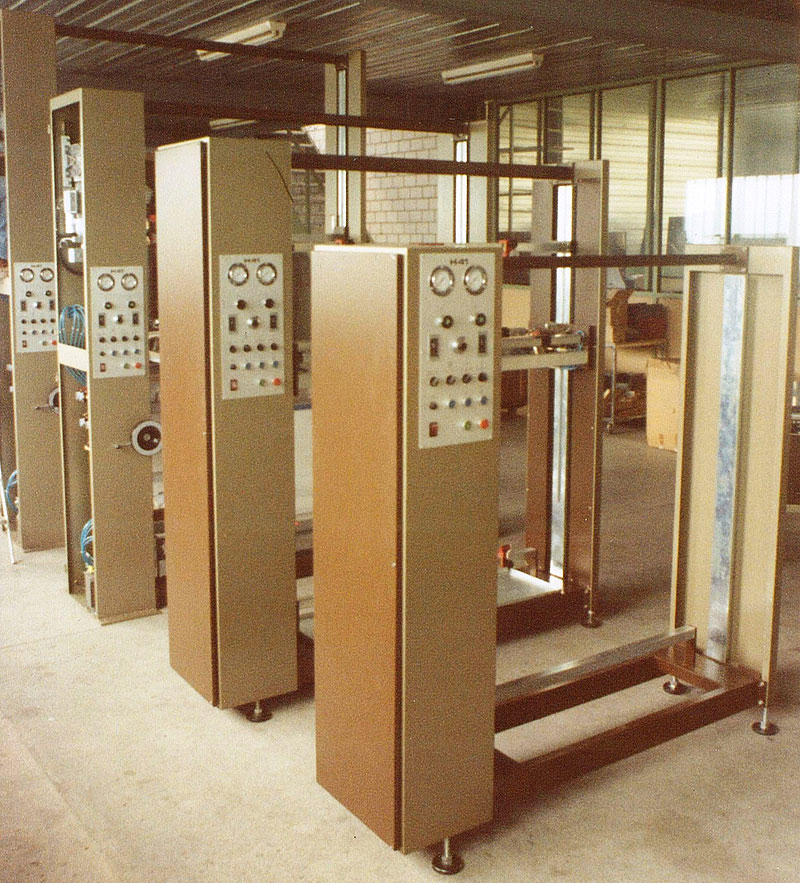

1979 The first automatic coating machine in the world, the H-41, is developed and manufactured.

1983 The first systems for automatic washing and de-coating are developed and installed throughout the world.

1984 is considered the hour of birth of the present G-WASH product range.

Up to 1992, the self-developed and –manufactured equipment is sold on a global market under the brand name „Harlacher“. After this date, the same products are internationally marketed under the brand name „Grünig“.

The generation change

2002 Marcel Grünig who represents the next generation takes over the reins of Grünig-Interscreen AG. This alternation of generations is marked by the construction of a new production building, a new branding and the appointment of Andreas Ferndriger as a member of the executive management.

2002 Marcel Grünig who represents the next generation takes over the reins of Grünig-Interscreen AG. This alternation of generations is marked by the construction of a new production building, a new branding and the appointment of Andreas Ferndriger as a member of the executive management.

2005 Corporate Design implementation with the new corporate identity GRUNIG and the sectors STRETCHING, COATING, WASHING

![]()

As a Swiss family enterprise, Grünig fully subscribes to the principle of self-development and –manufacturing. The core competences STRETCHING / COATING / WASHING are based on Swiss professionalism and quality. “Made in Switzerland” is not just an empty phrase but a commitment that is wholeheartedly implemented! Today, a clear and dynamic market presence rounds off the overall picture of Grünig.

The product lines

STRETCHING

For 50 years, Grünig has been building stretching machines in all sizes and designs. During this period, several thousands of stretching equipments and machines have been developed in every possible technical variation, from purely mechanical, pneumatic and electronic versions up to fully automatic stretching systems. The latest design covers the field of automatic gluing. An optimal coordination between the used glue system and the stretching equipment guarantees significant cost savings while maintaining the quality at a constantly high level.

G-STRETCH 275 UV BOND LED

Fully automatic stretching machine with automatic UV gluing and LED curing processes. The unique feature of this new design is the fact that – in addition to all the customary meshes – this machine is also capable of handling pre-coated PCF meshes.

COATING

Since the development of the first automatic coating machine in 1979, thousands of systems have been implemented all over the world. Whenever the need arises to enhance, standardize and automate the individual screen making processes, automatic coating is usually the first and most important step to be taken.

In all the market segments, major efforts are undertaken in order to improve the printing quality and lower the costs by standardizing the processes. In this context, screen preparation is of utmost importance. The PERFECT SCREEN is the mandatory prerequisite in order to achieve these goals.

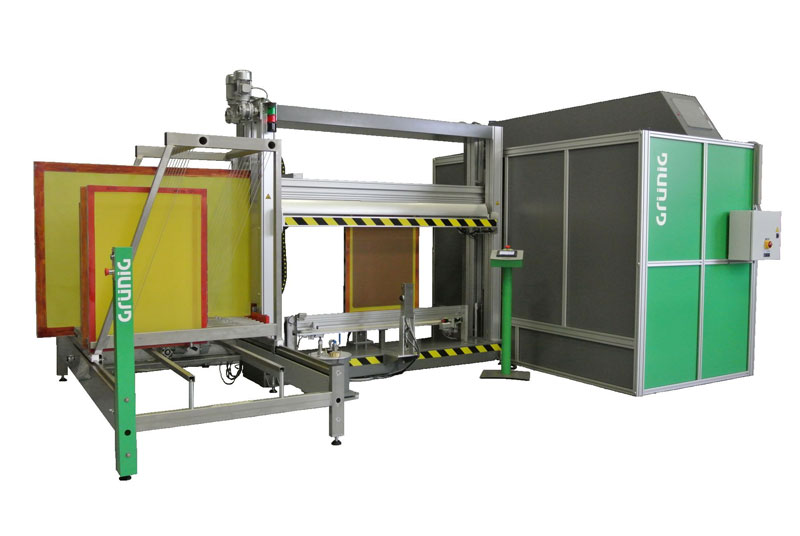

G-COAT 415 IN-LINE

IN-LINE Automation for an automatic coating and drying of printing screens. Standardized application of direct emulsion or capillary films with absolute precision.

WASHING

SCREEN AUTOMATION is a central and important aspect, especially in the field of screen cleaning. The extensive product range offers the ideal solution for all the customer segments and firm sizes, regardless if they require a single compact PLUG&WASH machine, if they need to handle small XS up to extremely large XXL formats, or if the optimal answer to their need consists in global IN-LINE AUTOMATION solutions that are becoming increasingly important. For more than 30 years, modular concepts have enabled Grünig to offer custom-tailored solutions.

G-WASH 170XM

Modular installation concept for all the WASHING processes: Automatic de-greasing, washing, de-coating and developing of printing screens of any size.

The strategic partner

2011 Marcel Grünig and Andreas Ferndriger acquired a share in the company Sign-Tronic AG, Widnau.

2011 Marcel Grünig and Andreas Ferndriger acquired a share in the company Sign-Tronic AG, Widnau.

Per June 2013 they took over 100% of the share capital, with the intention to ensure an optimal utilization of the synergies, to improve the competitive positioning of both companies, and to be able to offer the screen printers systematic and customized professional solutions for their various needs.

Both company headquarters at CH-3150 Schwarzenburg and CH-9443 Widnau are maintained. In spite of the close relationship between both companies, they remain legally independent entities. Marcel Grünig is the CEO of Grünig-Interscreen AG, whereas Andreas Ferndriger is Managing Director of Sign-Tronic AG and Sales & Marketing Director of Grünig-Interscreen AG.

The highly motivated staff members of both companies make the best possible use of the manifold available synergies to build their joint future. A dynamic team spirit has developed, so that in the meantime common appearances –such as during the FESPA 2017 trade fair in Hamburg – have become normal occurrences for the staff.

All the activities are coordinated and focused on automatic screen making. According to the motto „THE PERFECT SCREEN“, ingenious customer-specific overall solutions are designed to cover all the different requirements of the customers.

STM-TEX-PRO-10

Film-free CtS IN-LINE screen making guarantees not only top-notch screen quality but also unbeatable cost reductions. CtS direct exposure, combined with automatic screen development, blow-off/preliminary drying and feeder technology.

We love to be Grünig!

Highly qualified, motivated and flexible staff members used to be and still are the basis for any company’s success. Grünig is happy to count on quite a few long-term staff members who distinguish themselves by a high degree of identification. Anniversary celebrations for 20, 30 and even 40 years of company affiliation are regular events. On the occasion of international distributor meetings, many of their partners could find out in a humorous and charming manner how the team interprets the slogan „we love to be Grünig“. Other than flexibility and professionalism, humor and a zest for life are the hallmarks of Grünig.

Grünig continues to work with reliability, a spirit of innovation, a terrific team and a great deal of commitment and humor. As an enterprise, Grünig-Interscreen AG is and will remain small – but also – a global player on the screen printing market!

DE

DE  EN

EN